IN a small workshop in the hilly town of Yaoundé, the capital city of Cameroon, a set of unique machines roar day and night, helping produce one of the region’s favourite dishes. These “robots”, as their inventor calls them, allow operators to select, husk, grind and press pumpkin seeds, delivering the raw, husked seeds known locally as “egusi”, “ngondo” or “pistache”.

It took the inventor almost forty years to go from concept, to prototype, to filing an international patent, to finally producing his machines, which are the only made-in-Africa devices of their kind.

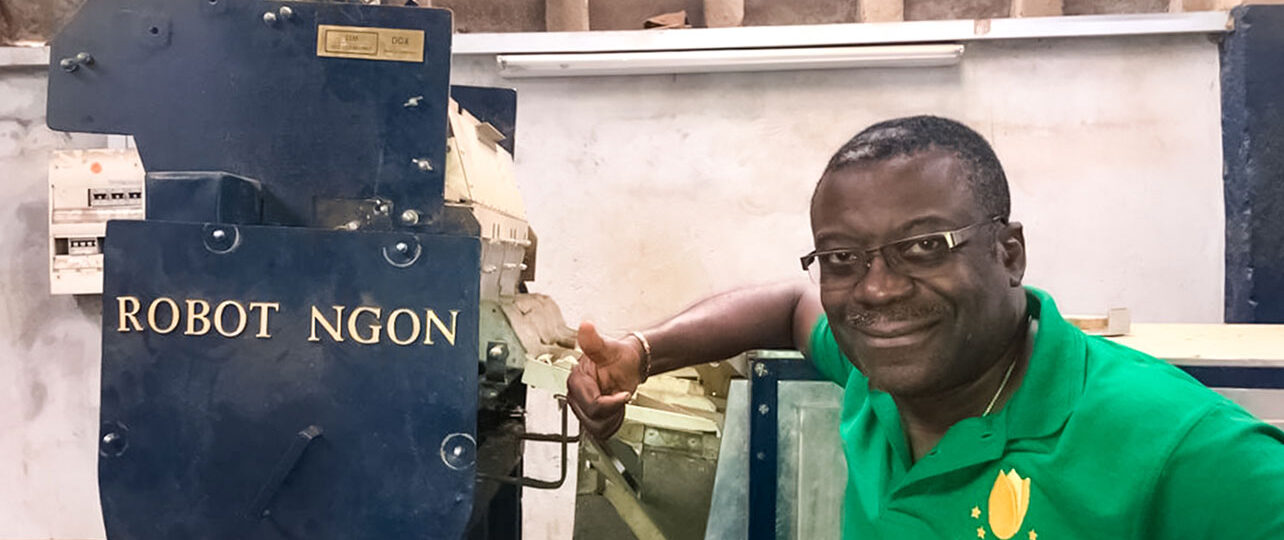

“Apart from here, this kind of machine doesn’t exist anywhere across Africa”, said Samuel Tchofo, a Cameroonian engineer in his sixties, the inventor of “Robot Ngon”, and founder of Sem Production.

To get to the beginning of the origin story required Tchofo to go all the way back to his early years after graduating as an engineer in 1982.

He had noticed how difficult it was to prepare egusi-based foods, common across Africa, because the seeds first needed to be husked, a very tedious task.

“I was a little bit sad when seeing these old women, mothers and grandmothers struggle to manually husk whole baskets of egusi. The task can take a couple of days just to husk a small basket”, he noticed.

He couldn’t help thinking that if pumpkin seeds probably had a similar importance in Western nations, someone in those countries would probably have invented a machine to solve the problem. “If so, why not in Africa?” So he decided to solve the problem himself.

The task, as it turned out, was huge. After being recruited by an oil sector company in 1984, Tchofo already had a good job in the petroleum industry. So he could only use his spare time and holidays to work on the project.

In the end, from the first design of the machines to the first prototypes and tests took him 27 years.

His very first prototype was made in June 1988, in Lyon, France, and was built during a holiday. However, the prototype was manual and had a very low output. The same year, he upgraded it, but the result was still unsatisfactory. Feeling like he was on the right track, however, he applied for a patent. The draft patent was approved and filed in 1989 with the Maisonnier firm in Lyon, France.

The oil engineer was subsequently posted to Algeria as an operations engineer, working on a 7-week rotation with a 3-week rest, in France. From then on, he took advantage of his frequent rest periods to continue his work, he explained.

In 2012, after taking an early retirement after 28 years in the oil and gas sector, he fully committed to his invention. It would take another four years until he was satisfied that his machine could be operated on a daily basis to process pumpkin seeds commercially. In 2017, he optimised a machine to process hard-shelled squash seeds.

Under the brand Ngon, the engineer also started selling a variety of products, highlighting the neglected value chain of the pumpkin seed.

“From “egusi”, we make and sell husked seeds, but also, what is less common, food oil, beauty oil, flour and cream”, he explained.

These products are now represented in hundreds of supermarkets and shops in Cameroon’s urban centres.

Sandra Ngoumou, 45, a teacher and mother of four and a regular consumer of pumpkin seed-based products in Douala, said she had been overjoyed to find a locally-produced source of pumpkin flour and oil.

“I discovered these products when shopping in a supermarket here in Douala. When I make cakes, I like to add some “pistache” flour in it. Egusi is a protein-rich product. I also regularly use “pistachio” oil in a number of recipes,” she told bird.

Tchofo is now working to attract investment to develop serial production of his “robots” in order to expand their presence across all rural areas in the region.

For small retailers of pumpkin seeds like Sarah Kouekam, the machine would be life-changing.

“I generally buy “pistache” from wholesale suppliers and I sell it to the market. It takes me a lot of time to husk it with my hands before selling,” she said, hoping the solution would soon be available to the public.

Almost forty years after first thinking he could change lives, Tchofo may finally be doing just that.